Magnesium Oxide (MgO) boards are increasingly popular in construction, especially for applications requiring fire resistance, moisture tolerance, and eco-friendly alternatives to traditional gypsum boards or plywood. Within the spectrum of MgO boards, there are two primary types based on the binder used: sulfate-based MgO boards and chloride-based MgO boards . Understanding the differences between these two is crucial for selecting the right board for a particular application.

1. Composition and Manufacturing

Sulfate MgO Board :

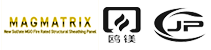

Sulfate MgO boards are primarily made of magnesium oxide (MgO), magnesium sulfate (MgSO₄·nH₂O), and other reinforcing fibers and fillers. The binder in sulfate MgO boards is magnesium sulfate, which is mixed with MgO under controlled conditions to create a paste that sets into a solid board. Some boards also include additives like fly ash, perlite, or wood fiber to improve strength and workability.

Chloride-based MgO Board:

Chloride-based MgO boards use magnesium chloride (MgCl₂) as the primary binder, combined with MgO powder. During manufacturing, MgO reacts with magnesium chloride in water to form a hardened structure, often reinforced with fibers such as glass, wood, or synthetic fibers. The chloride binder accelerates setting, which can influence production speed and board density.

Key Differences in Composition:

- Sulfate boards use MgSO₄ as the binder, while chloride boards use MgCl₂ .

- Sulfate boards generally incorporate fillers and fibers for strength, whereas chloride boards rely on the rapid chemical reaction of MgO and MgCl₂.

- Chloride boards can be more susceptible to chemical reactions if exposed to high humidity or water over time.

2. Physical Properties

| Property | Sulfate MgO Board | Chloride MgO Board |

| Density | Moderate, usually 850–1200 kg/m³ | Typically higher, 1000–1400 kg/m³ |

| Water Resistance | Excellent; sulfate binder is stable in moisture | Moderate; chloride may leach or react with water over long periods |

| Fire Resistance | Excellent; non-combustible | Excellent, similar to sulfate boards |

| Dimensional Stability | Very good; minimal expansion/shrinkage | Can experience slight expansion under prolonged moisture |

| Workability | Easy to cut, nail, and screw | Similar, but boards can be denser, making cutting slightly harder |

Sulfate MgO boards have an edge in moisture-prone areas due to their stability in wet conditions. Chloride-based boards, while fire-resistant, need more careful installation in humid environments.

3. Mechanical Performance

Impact Resistance:

Sulfate MgO boards offer reliable impact resistance, thanks to fiber reinforcement and stable bonding. They are less prone to cracking under normal mechanical stress. Chloride-based boards can be equally strong initially, but prolonged exposure to moisture may compromise their long-term mechanical stability.

Flexural and Compressive Strength:

Both types of boards have comparable compressive strength, often in the range of 8–12 MPa. Flexural strength can vary slightly: sulfate boards may perform better in bending applications due to fiber reinforcement, whereas chloride boards are denser and slightly more brittle.

Nail and Screw Holding:

Sulfate boards generally hold screws and nails well without cracking, making them suitable for wall fixtures, cabinetry, and partitions. Chloride boards can perform similarly but may require pre-drilling in denser variants.

4. Environmental and Health Considerations

Chloride Leaching:

A major concern with chloride-based boards is potential chloride leaching, especially in humid environments. Excess chloride can corrode steel framing and fasteners if the board is in direct contact. Sulfate boards do not present this risk, making them more compatible with metal studs and reinforcing components.

Indoor Air Quality:

Both types are generally safe for indoor air quality. Neither emits harmful VOCs like some synthetic materials. However, sulfate boards are often preferred in sensitive indoor environments due to their stability and lack of chemical leaching.

Sustainability:

Sulfate boards often incorporate industrial by-products like fly ash, enhancing sustainability. Chloride boards are also eco-friendly but may require stricter handling during production due to the corrosive nature of MgCl₂.

5. Installation Considerations

Cutting and Fastening:

Both sulfate and chloride boards can be cut with standard tools. Sulfate boards are slightly easier to machine, whereas chloride boards, being denser, may require more effort. Fastening is similar for both, but sulfate boards provide more consistent holding strength over time.

Jointing and Finishing:

Sulfate boards bond well with joint compounds and can be finished with paint, wallpaper, or tiles. Chloride boards can also be finished similarly, though the surface may require more preparation due to higher board density and surface alkalinity.

Moisture-Prone Areas:

Sulfate MgO boards are preferred for bathrooms, kitchens, or exterior sheathing due to superior water resistance. Chloride boards can be used indoors but are less ideal for high-humidity zones without protective coatings.

6. Cost and Availability

Sulfate MgO boards are generally more consistent in quality and slightly less expensive in the long term because they reduce maintenance concerns related to moisture and metal corrosion. Chloride boards may have a lower initial purchase price in some regions, but long-term risks associated with corrosion and water exposure can increase maintenance costs.

Availability depends on region and manufacturer. In some countries, chloride-based boards dominate due to faster production cycles, while sulfate boards are more common in areas emphasizing fire safety and moisture resistance.

7. Typical Applications

Sulfate MgO Board:

- Interior wall partitions

- Ceiling panels

- Wet areas: bathrooms, kitchens

- Fire-resistant walls

- Flooring underlay in humid areas

Chloride MgO Board:

- Dry area interior walls

- Ceilings where density and rigidity are preferred

- Fire-resistant applications in dry conditions

The choice between sulfate and chloride boards often comes down to environmental conditions and intended use. Sulfate boards excel in moisture stability and long-term durability , whereas chloride boards are useful in dry, controlled environments requiring dense, fire-resistant panels.

8. Advantages and Limitations

Sulfate MgO Board Advantages:

- High water resistance

- Excellent dimensional stability

- Non-corrosive to metal fasteners

- Good workability and mechanical performance

Sulfate MgO Board Limitations:

- Slightly lower density may reduce impact resistance in extreme cases

- Production can be slower than chloride-based boards

Chloride MgO Board Advantages:

- High density and initial rigidity

- Good fire resistance

- Faster setting in manufacturing

Chloride MgO Board Limitations:

- Susceptible to corrosion of metal components

- Moisture can compromise long-term stability

- Slightly more difficult to cut or fasten due to density

9. Conclusion

When comparing sulfate MgO boards to chloride-based MgO boards, it becomes clear that sulfate boards offer superior performance in wet environments, long-term durability, and compatibility with metal components , making them highly versatile for a wide range of construction applications. Chloride-based boards, while strong and fire-resistant, are best suited to dry areas and may require additional considerations for long-term performance, especially in moisture-prone settings.

Selecting the appropriate board requires evaluating environmental conditions, mechanical requirements, fire safety, and maintenance expectations . By understanding the differences in composition, mechanical properties, water resistance, and long-term stability, builders, designers, and homeowners can make informed decisions that align with project needs and sustainability goals.

BMSC 517 คณะกรรมการใหม่ซัลเฟตใหม่

BMSC 517 คณะกรรมการใหม่ซัลเฟตใหม่ บอร์ดฝักผนัง MgO ที่รองรับ

บอร์ดฝักผนัง MgO ที่รองรับ แผงลอย MGO ผนังปลอกหุ้ม

แผงลอย MGO ผนังปลอกหุ้ม กระดานฝักย่อย MGO Subfloor MGO

กระดานฝักย่อย MGO Subfloor MGO ความเพียร MGO Subfloor Sheathing Board

ความเพียร MGO Subfloor Sheathing Board Magmatrix MGO underlayment Panel/Board

Magmatrix MGO underlayment Panel/Board